Objectives of the Product

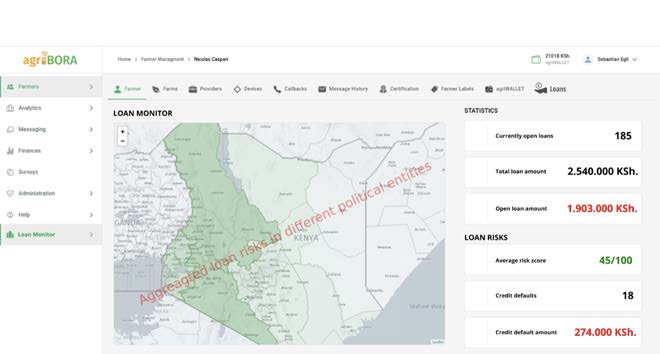

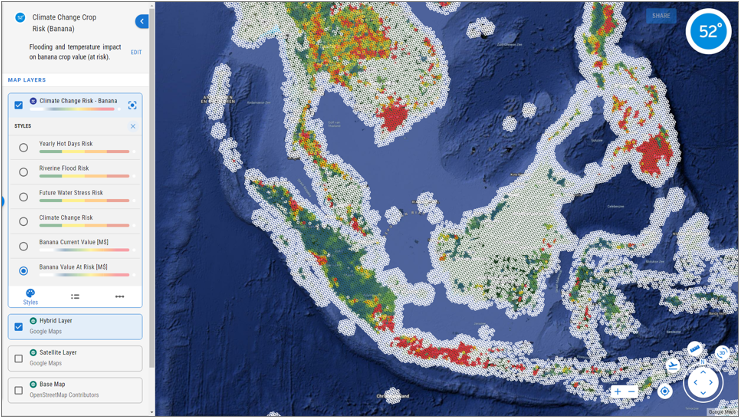

Climate Platform is an online platform where customers receive key information regarding their exposure to climate risks regarding the crops that they source and/or invest in. When customers access the online platform through password and login, they see their areas of interest in a dashboard, and will receive key information regarding climate risks of the crops of their interest in those areas. The climate risks identified include: droughts, flooding, temperature change, changing seasonality, overheating, frost, and water scarcity. We have chosen these parameters, because these parameters have a great effect on crops which hurt the business of our (potential) customers.

Customers and their Needs

Customers need an online platform that provides consistent and reliable data concerning the exposure of crops to climate risks. Our customers are characterised as multinationals that are active all over the world, who need climate information that they can directly use in their strategies and operations without additional processing. To satisfy those needs, Climate Platform provides multiple data layers and summarizing indicators, and comes with an easy-to-understand user interface.

Targeted customer/users countries

Climate Platform is a global service.

Target customer segments are the food & beverage industry and the financial sector. Potential clients from both segments are involved as pilot users of the service.

Product description

Climate Platform is an innovative service that provides insights regarding the (local) exposure of crops to climate change impact. The provided information has the following features:

- Global, comparable, up-to-date, and reliable data with predictive power.

- Scalable and cost efficient.

- Resulting in a data driven action plan

Climate risk related services currently available in the market have major limitations, including the following:

- Specialised knowledge is required to access the data.

- It is often unclear what the data means for the company; it is challenging to translate the data to the business. The risks are generic in the sense that they are not linked to business performance. Example: the increase in temperature is provided, but not what the impact will be of the temperature rise on the client.

- Some services only use historical data without integrating climate models, which limits their predictive value.

Added Value

Our service provides insights into the impact of climate change on crop production and business performance, which enables the mitigation of companies’ exposure to climate risks.

Example pains that we relieve include:

- Production sites are forced to close during the dry season for multiple months by the local government to safe water for the agricultural sector.

- Production sites are faced by high prices of crops that are needed for their production due to failed local harvests (due to higher temperatures for instance).

- A lower quality of foods and beverages are produced when the crops have lower quality.

- Shareholders demand more and more from companies to be transparent regarding their exposure to climate risks.

- Investments in agriculture are lost when climate risks are not taken into account (agricultural lands do not produce the expected volumes).

- Additional costs to mitigate climate risks of assets when climate risks are not estimated before investments are committed.

- Shareholders demand more and more from companies to be transparent regarding their exposure to climate risks.

Current Status

A prototype of climate platform is developed. 52impact is working on bringing the prototype to an operational service. The service is discussed with multiple potential customers. The focus is on how to integrate the service into existing processs of the clients.