Payload

Payload The Methane Satellite Camera (MSC) from HySpex addresses the urgent need for accurate and cost-effective monitoring of methane emissions. Methane is a highly potent greenhouse gas, and is the second greatest contributor to global warming, only second to carbon dioxide. To limit emissions of methane, upcoming regulations demand effective emission tracking. By optimising our camera for satellite use, we will provide a reliable solution for industries to identify and reduce methane leaks at large scales, contributing to global efforts to mitigate climate change.

HySpex MSC allows for rapid deployment of methane detection capabilities as it aims to be a space-proven commercial-of-the-shelf solution, building upon our decades-long experience building hyperspectral cameras.

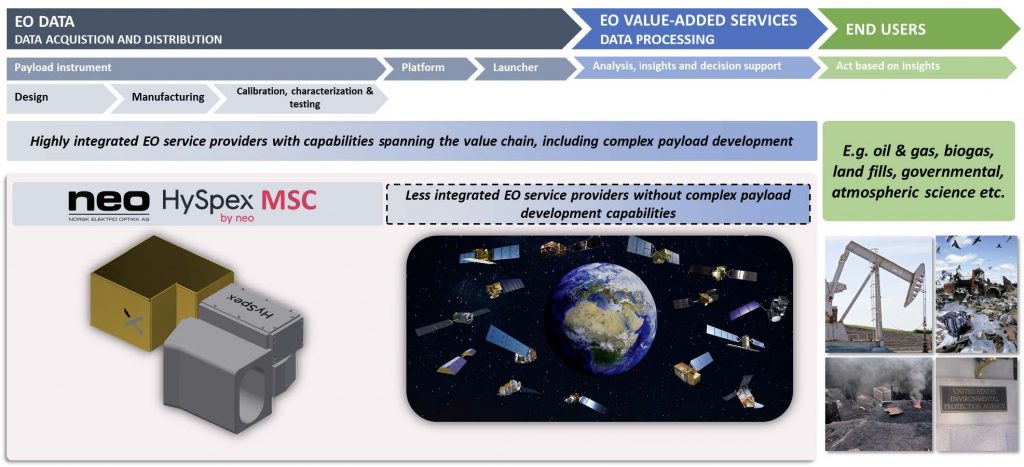

Target customers for HySpex MSC are Earth Observation (EO) satellite service providers within the energy and environmental sector that operate their own satellites and constellations.

Currently, if a satellite service provider wants to offer methane detection as part of their services, their only option is to design and build their own instrument capable of detecting methane. This is a complex task requiring substantial financial investments over several years, involving multiple stages of critical research, development, and testing. The process carries a high level of risk, with no guarantees that the system will work. Such development typically falls outside the core competencies of these companies, and they would prefer to avoid such high-risk projects. Our HySpex MSC provides a cost-effective, ready-to-use solution that eliminates the need for service providers to develop such custom instruments, thereby reducing both financial risk and time to market.

Global, but with specific focus on Europe and the US, who implement strict methane regulations.

HySpex MSC is a near-commercial off-the-shelf (COTS) instrument designed for methane detection from satellite platforms. Within the broader system and service ecosystem of its target users, HySpex MSC enables customers to launch and operate satellites capable of delivering high-resolution methane emission maps over large areas. This empowers end-users with actionable data for monitoring and mitigating methane emissions.

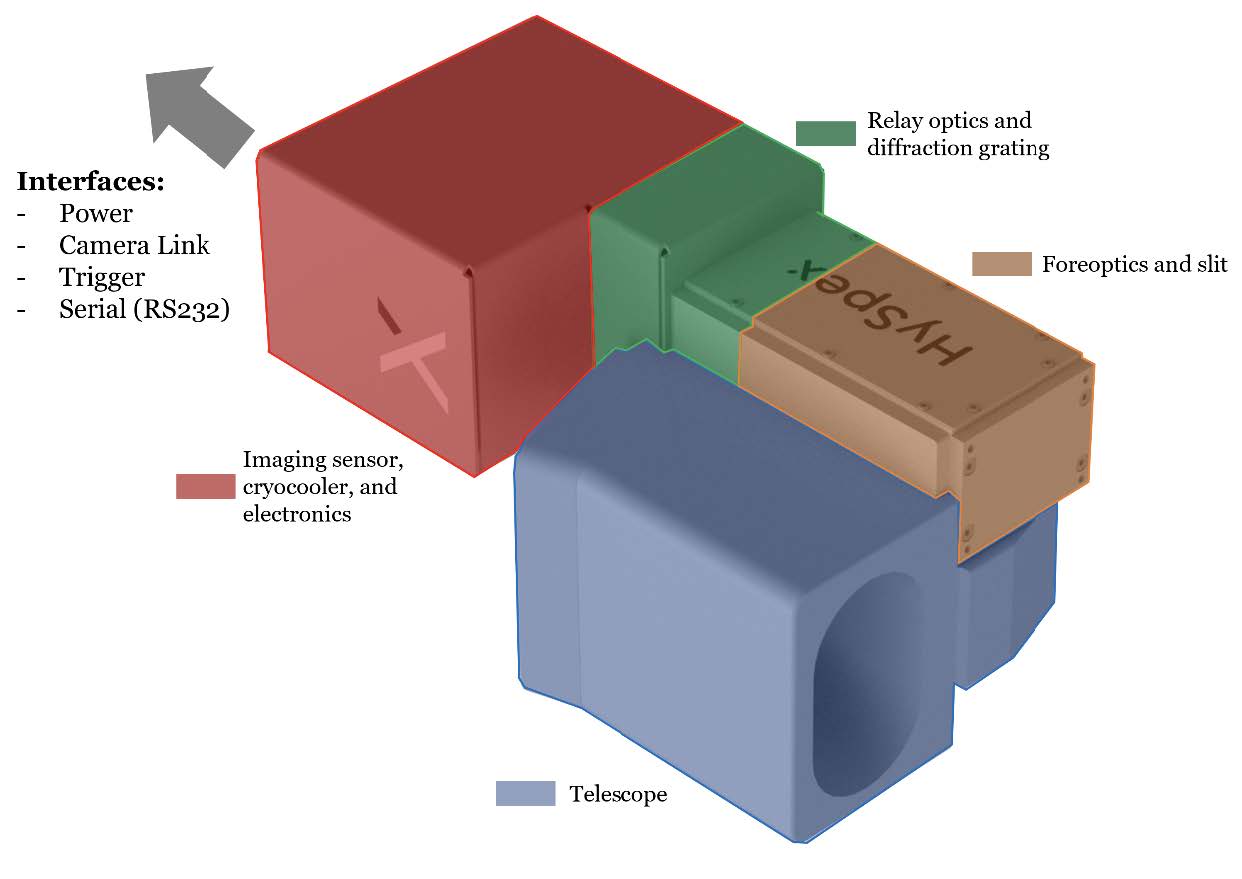

HySpex MSC incorporates our proven proprietary designs to achieve its mission. At its core it is a cutting-edge spectrograph design, integrated with a newly developed telescope and a diffraction grating optimised specifically for methane detection. Together, these components form a highly stable push-broom camera architecture.

Key performance highlights include:

This innovative combination delivers unparalleled accuracy and reliability in methane mapping, while providing a scalable, efficient solution for satellite missions.

HySpex MSC is the first commercially available, off-the-shelf (COTS) hyperspectral camera capable of detecting methane from space. This innovative instrument empowers less integrated Earth Observation (EO) service providers to access methane monitoring capabilities without the need for complex in-house development.

Currently, providers without such access face an overwhelming challenge: building their own methane detection payload. This process demands substantial financial resources, years of research and development, rigorous testing, and carries significant risks, with no assurance of success. HySpex MSC eliminates these barriers by offering a ready-to-deploy, low-risk alternative.

By bridging this gap in the EO value chain, HySpex MSC accelerates the adoption of methane monitoring globally. This directly supports efforts to combat climate change by enabling broader and faster deployment of EO services for methane tracking.

HySpex MSC’s streamlined approach significantly reduces costs, risks, and time-to-market, delivering unparalleled value over in-house development while fostering innovation across the EO industry.

Building upon the existing SWIR640 camera, HySpex MSC leverages HySpex proven spectrograph design, allowing for a short development cycle of only 12 months. Optical design and mechanical design of the new camera is well underway and will be completed early in the first quarter of 2025.